The holy grail of engineering is to be able to create strong but light structural components as this has a direct impact on cost and weight. Saving weight is the key to future efficiency, especially in EV vehicles with the extra weight of batteries.

The holy grail of engineering is to be able to create strong but light structural components as this has a direct impact on cost and weight. Saving weight is the key to future efficiency, especially in EV vehicles with the extra weight of batteries.

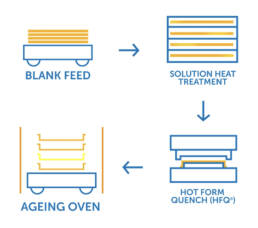

The HFQ® technology press forms hot aluminium blanks at high speed, which are quenched in the press tool, followed by artificial ageing to achieve full strength.

We are THE FIRST official licence holder for HFQ® technology for the UK and Europe. This revolutionary new process developed by the scientists at Imperial College, London, enables extremely complex aluminium parts to be formed in a single press operation, whilst achieving high levels of strength in the finished part using standard grades of aluminium. Using HFQ ®technology means that you can avoid design compromises.